90x190x64mm 22318CC/W33 bearing is made of chrome steel and steel cage. We have it in stock and can deliver it quickly.

Item No :

22318CC/W33Size (d*D*B) :

90x190x64mmLead Time :

3-5 daysWeight :

10KGShipping Port :

ChinaMOQ :

1| Cage material | Steel |

| Branding | famous brand/RMO/Neutral/OEM |

| Sealing | OPEN, 2RS |

| Material | Chrome steel (Gcr15) |

| Clearance | C3 |

| Shipping Port | GUANGZHOU, NINGBO, SHANGHAI |

| Payment | 100% TT, or 30% TT In Advance ,70% TT After Finished Production |

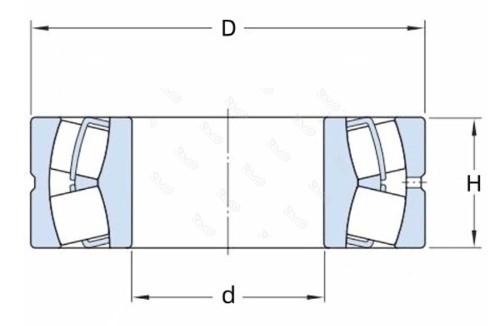

Self-aligning roller bearings are bearings in which cylindrical rollers are assembled between an inner ring with two raceways and an outer ring with a spherical raceway. They feature double rows of rollers, with the inner ring having two raceways that are inclined at an angle relative to the bearing's axis. The outer ring has a single common spherical raceway. This ingenious design endows it with self-aligning properties. The center of the outer ring raceway surface aligns with the bearing center, allowing it to function properly even when there is an angular error between the shaft and the bearing housing or when the shaft is bent.

The inner holes of self-aligning roller bearings come in two types: cylindrical and tapered. The tapered inner holes are further divided into two types with tapers of 1:30 and 1:12. The taper of 1:12 is denoted by the suffix K, and the taper of 1:30 is denoted by the suffix K30. When the tapered hole self-aligning roller bearings with the suffixes K and K30 are installed on the matching tight fit sleeves, they become the types with the suffixes K + H and K30 + H, respectively, which are suitable for applications where the bearings need to be frequently installed and disassembled. To enhance the lubrication performance of the bearings, three evenly distributed oil holes are drilled in the outer ring of the bearings, and a circumferential oil groove is machined. The suffix for this type is W33.

1. High load-bearing capacity.

2. Good self-aligning performance.

3. Suitable for high-speed operation.

4. Adaptability to complex working conditions.

| Model No. | d | D | H | m | Model No. | d | D | H | m | |

| 22308E | 40 mm | 90 mm | 33 mm | 1.05 KG | 22324CC/W33 | 120 mm | 260 mm | 86 mm | 23 KG | |

| 22309E | 45 mm | 100 mm | 36 mm | 1.4 KG | 22326CC/W33 | 130 mm | 280 mm | 93 mm | 29 KG | |

| 22310E | 50 mm | 110 mm | 40 mm | 1.9 KG | 22328CC/W33 | 140 mm | 300 mm | 102 mm | 36.5 KG | |

| 22311E | 55 mm | 120 mm | 43 mm | 2.45 KG | 22330CC/W33 | 150 mm | 320 mm | 108 mm | 43.5 KG | |

| 22312E | 60 mm | 130 mm | 46 mm | 3.1 KG | 22332CC/W33 | 160 mm | 340 mm | 114 mm | 52 KG | |

| 22313E | 65 mm | 140 mm | 48 mm | 3.75 KG | 22334CC/W33 | 170 mm | 360 mm | 120 mm | 61 KG | |

| 22314E | 70 mm | 150 mm | 51 mm | 4.55 KG | 22336CC/W33 | 180 mm | 380 mm | 126 mm | 71.5 KG | |

| 22315E | 75 mm | 160 mm | 55 mm | 5.55 KG | 22338CC/W33 | 190 mm | 400 mm | 132 mm | 82.5 KG | |

| 22316E | 80 mm | 170 mm | 58 mm | 6.6 KG | 22340CC/W33 | 200 mm | 420 mm | 138 mm | 95 KG | |

| 22317E | 85 mm | 180 mm | 60 mm | 7.65 KG | 22344CC/W33 | 220 mm | 460 mm | 145 mm | 120 KG | |

| 22318E | 90 mm | 190 mm | 64 mm | 9.05 KG | 22348CC/W33 | 240 mm | 500 mm | 155 mm | 155 KG | |

| 22319E | 95 mm | 200 mm | 67 mm | 10.5 KG | 22352CC/W33 | 260 mm | 540 mm | 165 mm | 190 KG | |

| 22320E | 100 mm | 215 mm | 73 mm | 13.5 KG | 22356CC/W33 | 280 mm | 580 mm | 175 mm | 235 KG | |

| 22322E | 110 mm | 240 mm | 80 mm | 18.5 KG | 22380CA/W33 | 400 mm | 820 mm | 243 mm | 650 KG |

⚙️Precautions:

| 1. Keep clean | 2. Use with caution | 3. appropriate tool | 4. Hot-loading | 5. Be careful of rust |

| Dust will have a bad effect on the bearing, so keep the surrounding clean. | Strong impact during use can easily cause scratches and indentations. | Avoid replacing existing tools, and use appropriate tools. | Bearings are precision parts, so hot installation is recommended. | Sweat on your hands during operation will cause rust, so it is best to wear gloves. |

|

|

|

|

|

|

|

|

|

Hi! Click one of our members below to chat on